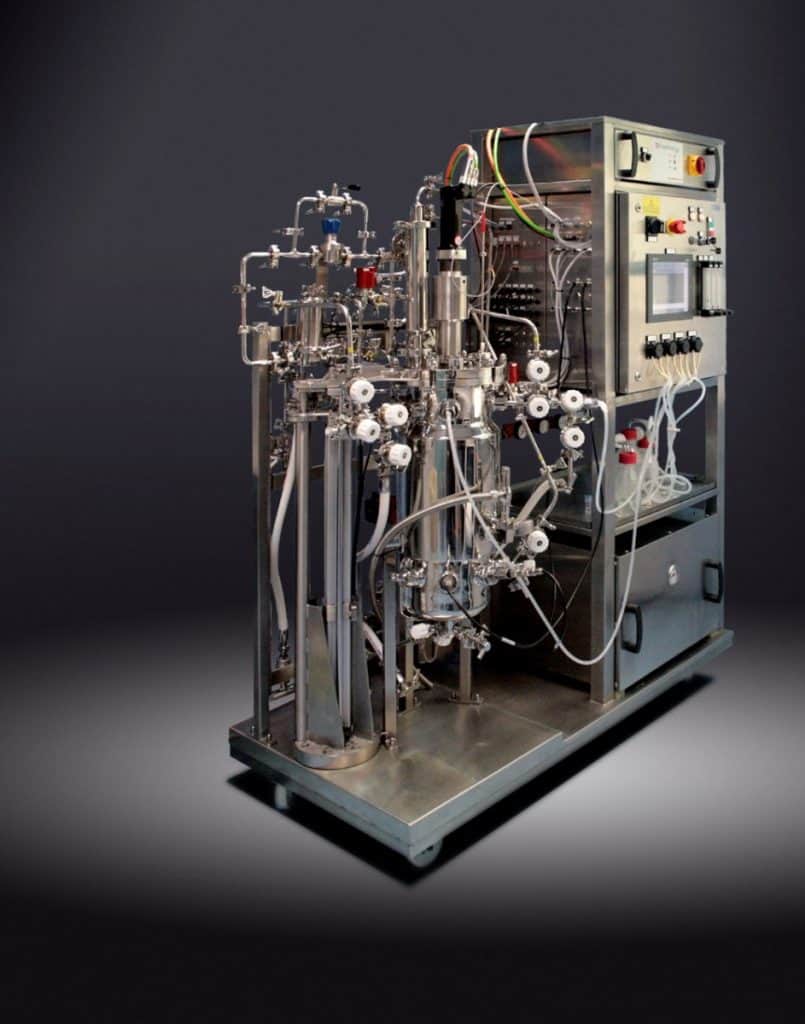

Modular Laboratory in situ Sterilisable Bioreactors & Fermenters from 3 Litres to 50 Litres volume

The modularity concept has been extended to our lab/pilot SIP in-situ sterilisable bioreactors and fermenters with leading industrial hardware and software technologies, modular and compact designs; available as pre-assembled SIP bioreactor packages or custom-made solutions based on detailed customer requirements.

The modularity concept has been extended to our lab/pilot SIP in-situ sterilisable bioreactors and fermenters with leading industrial hardware and software technologies, modular and compact designs; available as pre-assembled SIP bioreactor packages or custom-made solutions based on detailed customer requirements.

The major advantage of the modularity of Solida’s bioreactors is the ability to integrate and replace any module at any time and to interchange a wide range of culture vessels in bacteriological or cell cultivation configurations in 3, 5, 7, 10, 15, 20, 30, 40 and 50 litre volumes.

The BIO-SIP Lab range is a direct upscaling of the BIO-BENCH series of lab scale autoclavable bioreactors. Consistent controller and software platforms simplify upscaling and minimise the risk in transferring processes to the next level.

The contained footprint minimises space utilisation in the lab. All systems are fully documented for GLP and cGMP usage and are supplied with an extensive package of documentation to support validation.

Applications include

Lab-scale fermentation of aerobic and anaerobic bacteria, yeast, and fungi

Cell culture of mammalian, insect and human cell lines

Stem cell culture, vaccine, monoclonal antibody

Renewable energies, biofuel/biopolymer R&D.

Features

- Industrial design for easier upscaling and technology transfer

- PLC industry standard controller combined with a unique modular design for greater flexibility and expandability

- Leading master controller with interchangeable vessels from 3 litre to 50 litre volume

- Parallel bioreactors operations with powerful superior BIOFLEX™ control software supports sophisticated process control, comprehensive data and information management and design of experiments (DoE)

- Advanced process development built around Quality by Design (QbD) standards.