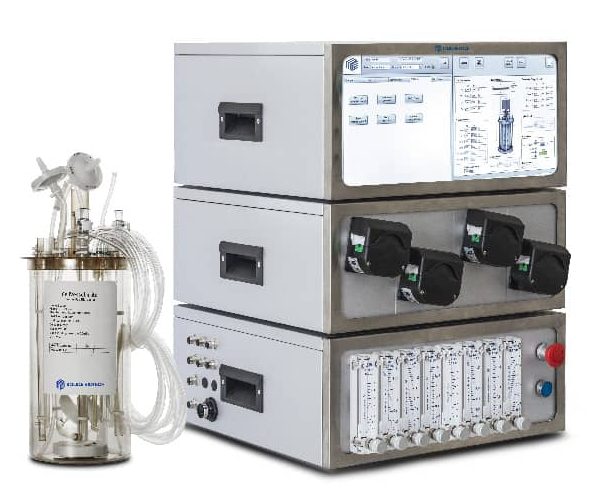

SIP/CIP Industrial 20L-30m3 Bioreactors and Fermenters

SOLIDA BIOTECH design, engineer and manufacture high quality custom Pilot & Industrial Bioreactors & Fermenters up to 30 cubic metres. Our portfolio contains a powerful range of engineering and manufacturing solutions that have been integrated to address the process and equipment needs critical to the cell growth process. Our custom solutions meet industry best practice and local regulatory requirements. Culture vessels in bacteriological or cell cultivation configurations from 20 litre up to 30 cubic metres volumes.

We provide extensive aftermarket service and support, including spare parts, equipment upgrades, servicing and maintenance, and customer training.

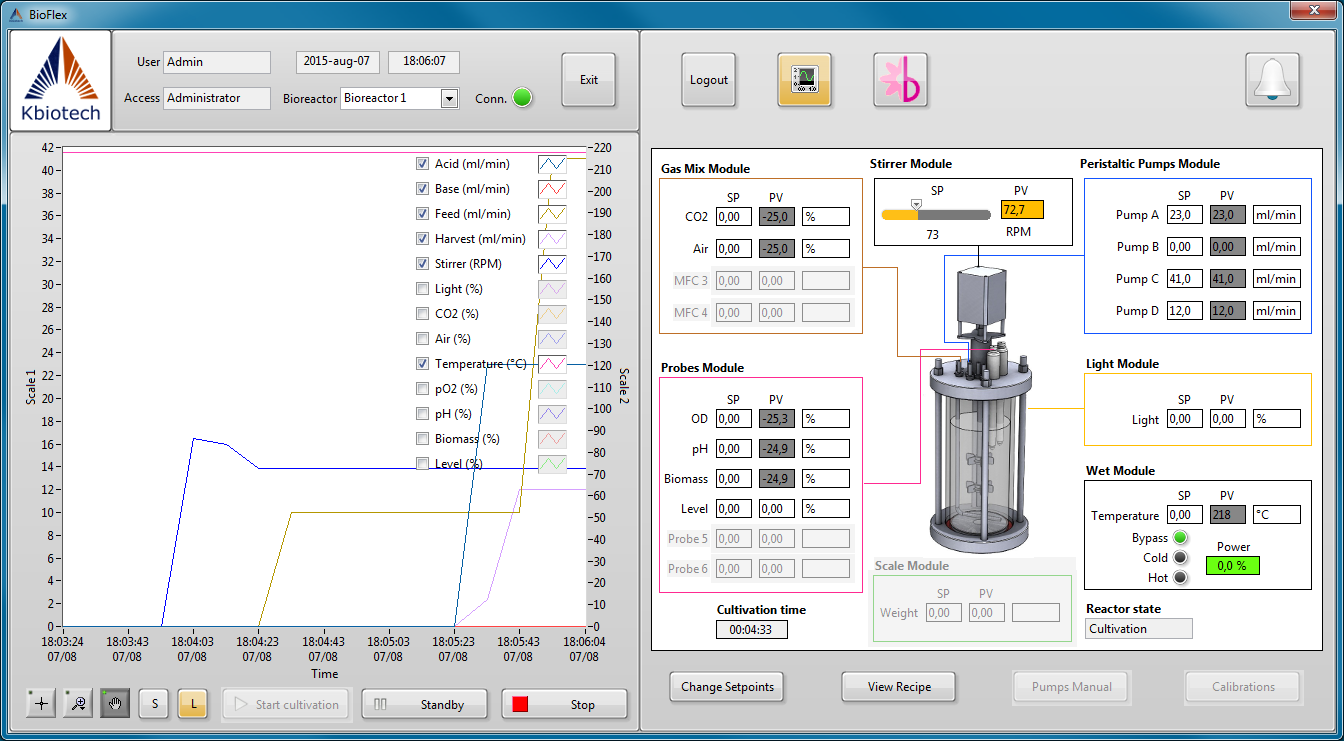

Solida industrial systems are designed and manufactured for easy operation, accessible components and have safety in mind:

- Clean steam, sterile gas, and product contact lines are orbitally butt welded to the maximum extent possible.

- Our approach to equipment design is to engage in a discussion of detailed project requirements with our customers.

- We ensure that our proposal meets the technical process, time to market and commercial requirements for the completion of a successful project.

- The main objective of Solida Biotech is to provide our clients with turn-key solutions for the engineering and technical management of their projects so they can achieve the best targets.

- Solida Biotech will assist you in procuring and delivering to the production plants all the necessary supplies, equipment, and instrumentation from lab scale to production and final formulation and manufacturing of the products.